Detailed description

Main Usage:

The machine is made up of three parts: main machine, auxiliary machine and electric control box. It has the properties of wind selection, having no sieve or net, and an even granularity of the processed material. The production process going on continuously, the machine can undertake the grinding of chemical products .food .medicines, medicament, cosmetics, plastic, dyestuff, resin .grain, etc.

Specialty:

The design is compact and structure is reasonable. The machine is equipped with an internal classification mechanism so that grinding and classification are carried out simultaneously, thus reducing energy consumption.

Euipped with a draught fan, which dissipates the heat in the machine continuously, the machine is fit for the grinding of thermal sensitive materials.

Having a great adaptability and narrow granularity distribution. The granularity of the product is even and fineness may reach 80-320 mesh.

Regulate the speed of the classifier or amount of the air without stopping the machine and evenly distributed products of the required granularity will be obtained.

The top cover of the main machine is opened with pneumatic springs and the body is contructed in such a way that it may be opened to two sides so that no hindrance will be met in cleaning and servicing the internal parts.

The main grinding parts are made of high-grade alloy tool steel so that the service life or change cycle of the wear parts is greatly lengthened.

High-speed precision bearings imported from abroad are adopted for the bearing system so that the whole machine runs smoothly with little vibration and noise.

The pipes are of quick-detachment construction, making detachment and cleaning quick and convenient.

Equipped with a cyclone separator and a collector, so there is no powder flying during production. The dust collecting bag can effectively collect the fine powder in the air current so as to meet the requirements for cleanness and environmental protection in waste gas discharge.

The fine powder collected by the dust collecting bag can be effectively recycled. thus the material loss is reduced.

Main Usage:

The machine is made up of three parts: main machine, auxiliary machine and electric control box. It has the properties of wind selection, having no sieve or net, and an even granularity of the processed material. The production process going on continuously, the machine can undertake the grinding of chemical products .food .medicines, medicament, cosmetics, plastic, dyestuff, resin .grain, etc.

Specialty:

The design is compact and structure is reasonable. The machine is equipped with an internal classification mechanism so that grinding and classification are carried out simultaneously, thus reducing energy consumption.

Euipped with a draught fan, which dissipates the heat in the machine continuously, the machine is fit for the grinding of thermal sensitive materials.

Having a great adaptability and narrow granularity distribution. The granularity of the product is even and fineness may reach 80-320 mesh.

Regulate the speed of the classifier or amount of the air without stopping the machine and evenly distributed products of the required granularity will be obtained.

The top cover of the main machine is opened with pneumatic springs and the body is contructed in such a way that it may be opened to two sides so that no hindrance will be met in cleaning and servicing the internal parts.

The main grinding parts are made of high-grade alloy tool steel so that the service life or change cycle of the wear parts is greatly lengthened.

High-speed precision bearings imported from abroad are adopted for the bearing system so that the whole machine runs smoothly with little vibration and noise.

The pipes are of quick-detachment construction, making detachment and cleaning quick and convenient.

Equipped with a cyclone separator and a collector, so there is no powder flying during production. The dust collecting bag can effectively collect the fine powder in the air current so as to meet the requirements for cleanness and environmental protection in waste gas discharge.

The fine powder collected by the dust collecting bag can be effectively recycled. thus the material loss is reduced.

Technical parameter

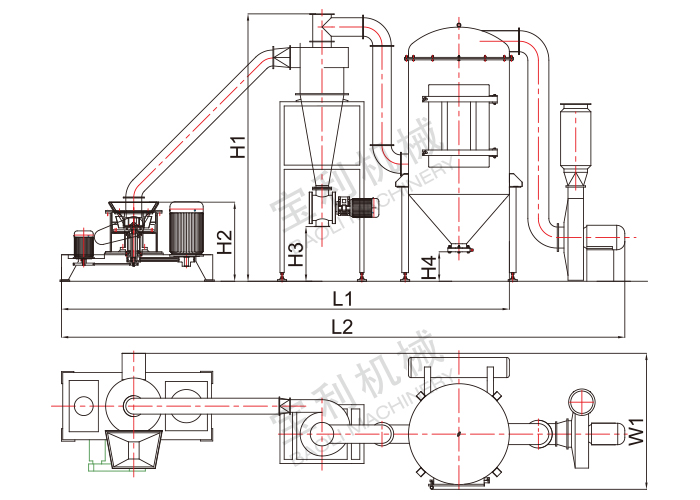

| Model | Main Structural Dimensions(mm) | Capacity | Input Particle Size | Output Particle Size | Speed | Machine weight | Total power | ||||||

| L1 | L2 | H1 | H2 | H3 | H4 | W1 | Kg/H | mm | mm | rpm | Kg | KW | |

| JB-15 | 3950 | —— | 2640 | 850 | 650 | 350 | 1450 | 10-150 | <6 | 60-320 | 1100 | 600 | 13.5 |

| JB-20 | 4300 | 5900 | 2800 | 850 | 650 | 350 | 1450 | 15-200 | <10 | 60-320 | 1300 | 5400 | 21 |

| JB-30 | 5250 | 7050 | 3200 | 950 | 650 | 350 | 1550 | 50-600 | <12 | 60-320 | 2000 | 3800 | 46 |

| JB-60 | 6100 | 8100 | 3700 | 1050 | 650 | 400 | 2000 | 100-1000 | <15 | 60-320 | 3800 | 2900 | 84 |

| JB-80 | 7200 | 9200 | 4250 | 1150 | 650 | 400 | 2300 | 120-1800 | <15 | 60-320 | 5100 | 2500 | 123 |

| JB-100 | 7900 | 10100 | 4500 | 1250 | 650 | 400 | 2500 | 150-2000 | <20 | 60-320 | 7400 | 2000 | 183 |